By Emma Quinn, Gerhard Schneider and Michal Krupa (CERN)

This May, the first Beam Position Monitor (BPM) for the HL-LHC finished its in-house production in the CERN ateliers. The BPM is now ready for assembly with the new beam screen and will be installed in the first HL-LHC Inner Triplet cryomagnet (Q1).

A BPM is a non-destructive diagnostic device, used to measure the transverse position of the beam. It uses four electrodes to pick up the electromagnetic field of the beam bunches as they travel through the instrument in a vacuum chamber.

The HL-LHC BPMs have a brand-new design to improve performance and meet the challenging requirements that higher luminosity and energies will bring. Most of the HL-LHC BPMs will be installed in the sections of the accelerator where both beams share a common vacuum chamber. To be able to distinguish between the two counter-rotating beams, the BPM uses long stripline electrodes which were manufactured and installed with tolerances of tens of micrometres.

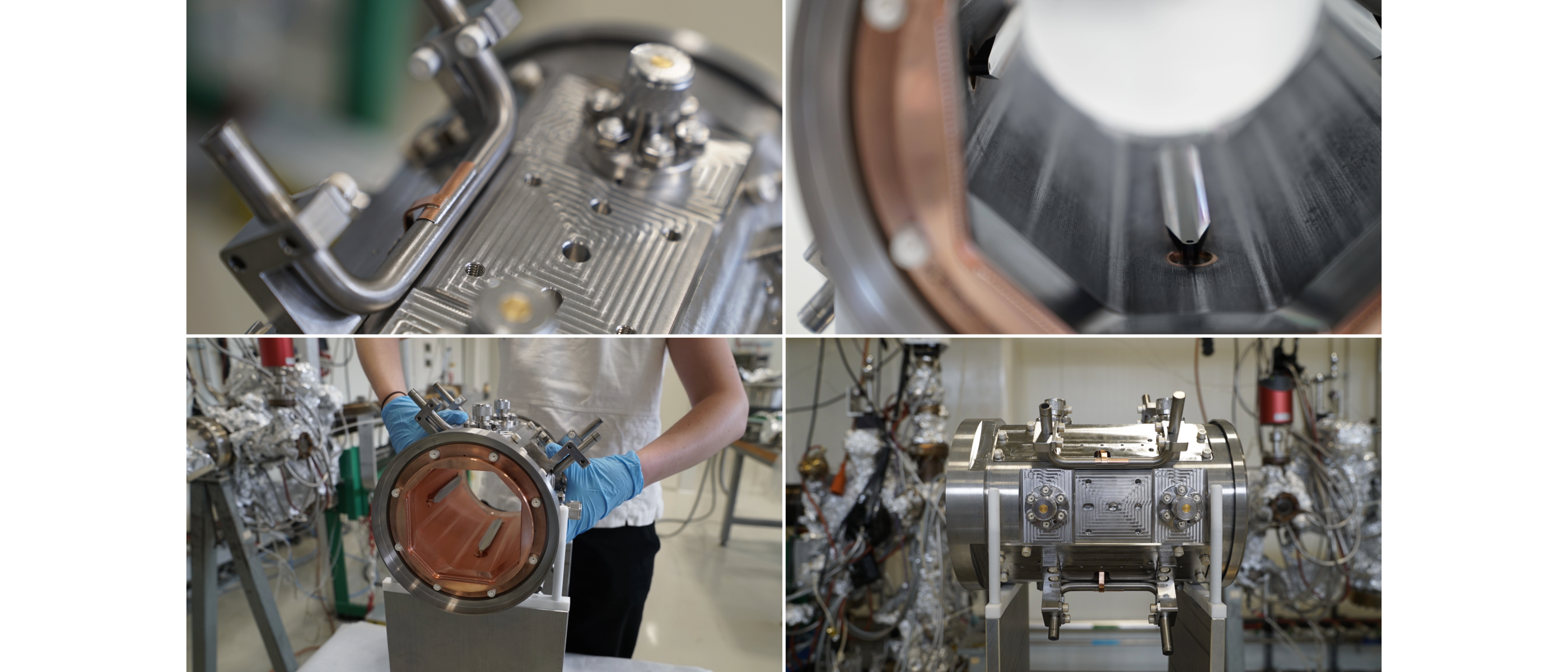

Copper-brazed thermal link which is attached to tungsten blocks buried within the BPM (top left), the BPM before (bottom left) and after (top right) amorphous Carbon coating, and a view from the side of the BPM (bottom right). Florence Thompson / CERN.

Being integrated into the cryostat, this cryogenic BPM has laser-welded external tubes for cooling the instrument with liquid helium. The stainless-steel tubes have a laser welded, copper-brazed, thermal link attached to tungsten blocks buried within the BPM vacuum chamber. These blocks absorb the higher levels of radiation that the BPM will experience from the particle debris created from the high-energy collisions at the LHC experiments.

The octagonal inner aperture of the BPM is electroplated with a gold flash and 0.1 mm-thick layer of copper, to minimise the power dissipation from beam impedance and ensure temperature uniformity. At each end of the BPM, its inner shape is adapted to that of the adjacent vacuum chambers by copper transitions, which are electron beam welded with RF fingers to assure low impedance. The final stage of production is an ultra-thin coating of amorphous Carbon, applied via plasma spluttering. This coating is a new step in manufacturing for the HL-LHC, used to limit electron cloud production by reducing the Secondary Electron Yield (SEY).

This milestone represents the hard work and collaboration of CERN’s ateliers and experts, ensuring every step of fabrication and quality assurance meets the highest standards. The full production run includes 38 cryogenic BPMs of three different types, all designed and manufactured in-house for the HL-LHC Inner Triplet upgrade at Interaction Points 1 and 5.