By Florence Thompson (CERN)

The first beam screen in the series for the HL-LHC has been coated with new amorphous carbon coating.

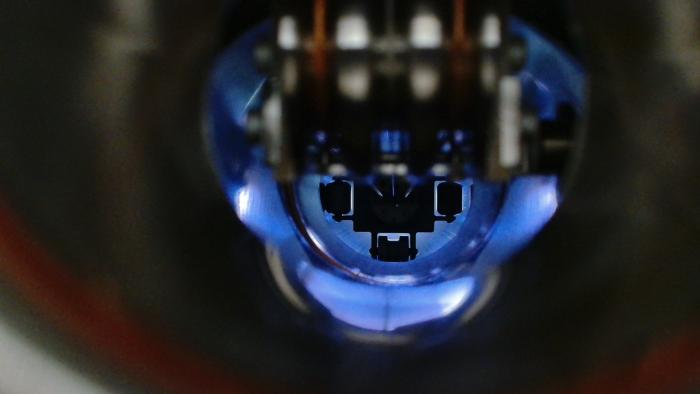

For the HL-LHC, the inner triplet region (the final focusing region either side of the experiments CMS and ATLAS) will be fitted with new beam screens. Beam screens are the first layer around the beam, and their role is to reduce heat load and radiation-induced damage to the cold mass and ensure vacuum performance.

In the LHC, the beam screens are made of stainless steel and a copper cladding. The new ones will be equipped with tungsten alloy shielding and will be coated with an amorphous carbon coating on the inside.

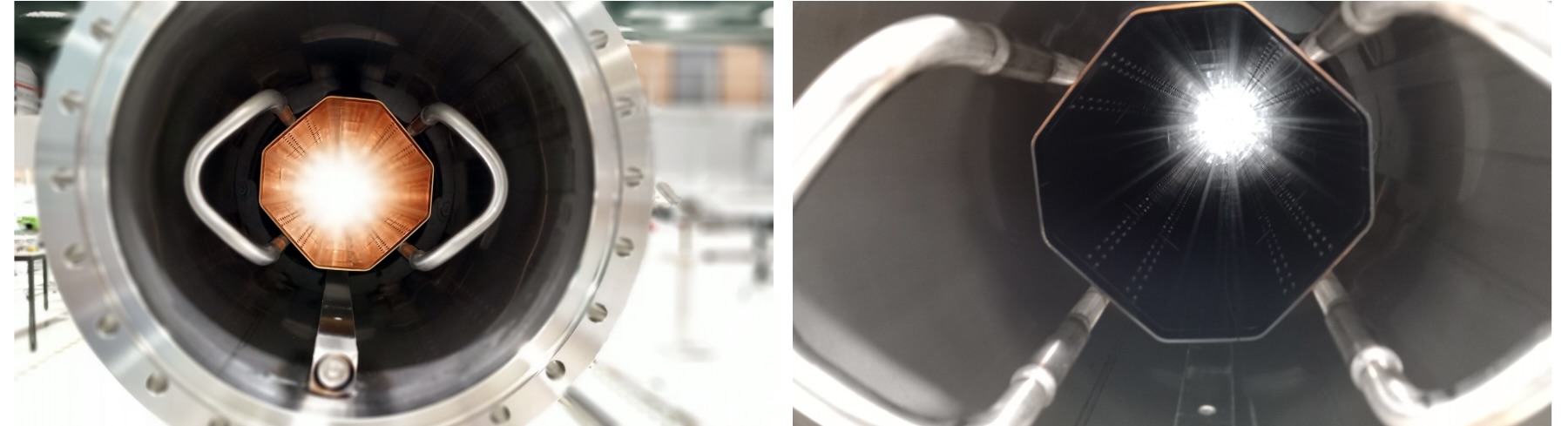

Figure 2. Beam screen before (left) and after (right) coating. Photos: Pedro Costa Pinto / CERN

This amorphous carbon coating will decrease the release of secondary electrons from the beam screen itself, avoiding the formation of electron clouds and therefore reducing the heat load to the cryogenic system as much as possible.

A 100-nanometres-thick layer of carbon is enough to decrease the multiplication of electrons below the threshold for the formation of electron clouds. However, the quality of the carbon depends strongly on the incorporation of impurities.

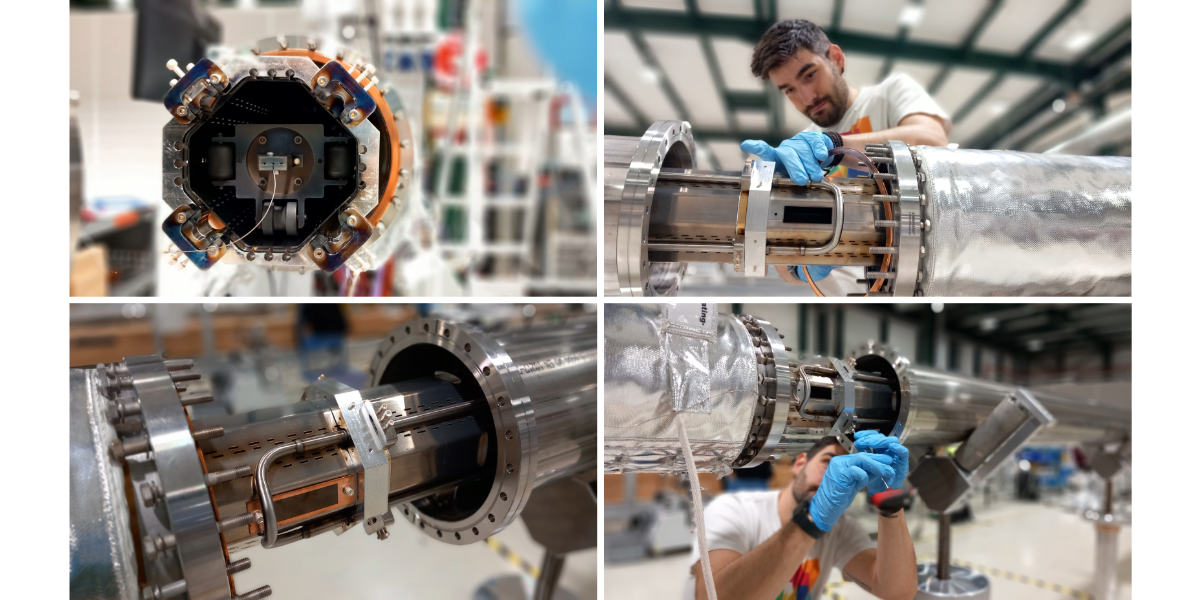

Figure 3. Coupling of the beam screen device to the coating system. Photos: Bernard Henrist / CERN

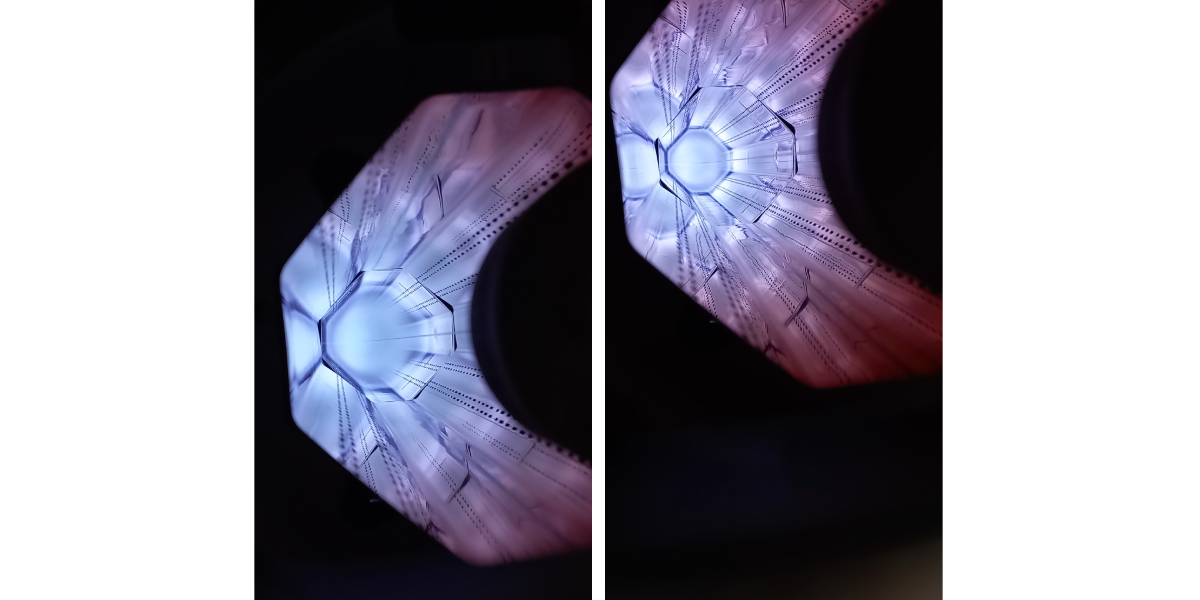

‘The coating technology was entirely designed and constructed at CERN and includes the preparation of the copper surface with argon ions bombardment, to enhance adhesion, and the deposition of a pre-layer of titanium to pump hydrogen and reduce impurities in the carbon coating’, says Pedro Costa Pinto, applied physicist in charge of the development and production of the carbon coatings.

The coating of the first shielded beam screen of the series has now been completed, and this sets the project up well for continuing the production and coating of the full series of 29 units (24 needed for installation with 5 spares).

‘The construction of these new beam screens was a complex procedure, as this was a completely new technology compared to the LHC, and we had to insource a lot of activities for this process,’ says Cedric Garion, project engineer in charge of the HL-LHC beam screens. ‘The completion of the first unit has provided a lot of valuable learning for us to optimise the procedure of the production and coating of the remaining beam screen units’.

Figure 4. Beam screen during argon ion etching. Photos: Bernard Henrist / CERN

Related content

Photos of first series beam screen coated here and here

Previous article and photos on the amorphous carbon coating production - September 2024